Your Reliable Partner in Extrusion since 2006

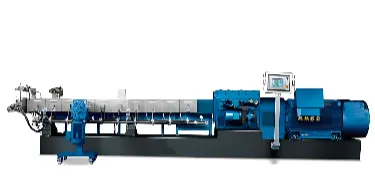

Twin Screw Extruder Manufacture

- Reliable, Efficient, and Flexible Extruders for Every Polymer

- High Specific torque 14Nm/cm³, Max. screw speed 1200rpm, Max. process temp ≥450C

- modular customization, and low-maintenance operation—delivering consistent quality, higher output, and lower costs.

Your Reliable Partner in Extrusion since 2006

Twin Screw Extruder Manufacture

- Reliable, Efficient, and Flexible Extruders for Every Polymer

- High Specific torque 14Nm/cm³, Max. screw speed 1200rpm, Max. process temp ≥450C

- modular customization, and low-maintenance operation—delivering consistent quality, higher output, and lower costs.

With 20+ years in twin-screw extrusion, VJJ delivers advanced, affordable machinery and expert service to create sustainable value for clients.

High performance twin-screw extruders stable output, versatile processing, energy-saving, and easy to operate for lower costs and higher quality

We provide end-to-end compounding solutions—from handling to pelletizing—delivering efficient, reliable systems tailored to your production goals.

Extruders & Compounding Machines

Twin ScrewExtruder machine, Laboratory Extruders, filitration compounder, two stage compounder

Customized Extrusion Production

- raw material handling

- dosing

- compunding

- packaging and storage

Raw Material Handling – Efficient, precise, and reliable preparation for extrusion.

Dosing – Accurate delivery of each material for consistent, high-quality output.

Compounding – Uniform blending of materials to achieve tailored properties.

Packaging & Storage – Homogenization, drying, cooling, and automated packing.

Engineered for Precision, Efficiency & Reliability

Twin-screw extruders engineered for stable performance, precise mixing, lower energy use, and reduced costs with a greener footprint.

High Performance & Efficiency

Twin-screw extruders are engineered for high Output range from 20 kg/h up to 5,000 kg/h, lower energy consumption up to 20%, Reliable 24/7 operation with minimal downtime

Trusted Worldwide

500+ extruders delivered to 30+ countries, trusted by global leaders, with proven results like 35% higher throughput.

Precision Feeding solutions for plastics

Our feeders provide continuous, accurate, and reliable feeding for all materials. Single- and twin-screw, liquid, or vibratory options ensure precise results every time.

Advanced Twin-Screw Technology

Achieve efficient masterbatch processing with 11.3 Nm/cm³ torque, 900 rpm screw speed, quick-change heads and feeders, and a modular barrel design (24–68 D) for maximum flexibility and performance.

Tailored Solutions & Flexibility

Modular screw and barrel designs for fast configuration in engineering plastics, masterbatch, recycling, and specialty materials like biodegradable or pharmaceutical HME.

Quality & Reliability

European-standard steel, CNC precision, Siemens/ABB/Schneider electricals, ISO & CE certified—durable with low maintenance.

Our services

More than machine maintenance, we offers full cooperation and experts consulting

Spare Parts

24h express delivery, emergency stock, obsolete part alternatives, and fast gearbox/barrel replacement to keep your operations running.

repair&maintenance

Ensure plant uptime and efficient resource use, with maintenance for various well-known gearbox brands

service Consulting

profitability analysis, engineering, troubleshooting, maintenance and energy efficient production.

modernization

We offer practical modernization services, both mechanical and electrical.

training

Training your staff for efficient operation and maintenance of complex machinery

Remote Monitoring & Online Support

24/7 remote diagnostics and assistance for faster problem-solving and predictive maintenance.

About Us

VJJ Extrusion specializes in high-torque twin-screw extruders, with decades of experience in pharmaceuticals, chemicals, and compounding. With screw sizes from 8mm to 177mm and torque up to 14Nm/cm³, we deliver reliable, efficient, and intelligent extrusion systems. Headquartered in Chengdu with nationwide offices and a demo center in Changzhou, we provide complete line design and professional service to support diverse industry needs.

Trusted by Our Global Clients

we deliver reliable, and high-quality twin screw extruder machine. See what our clients have to say about their experience working with us.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

We provide 13monthes since of B/L date. During this period, any quality or performance issues are covered, and our engineers will provide remote support as needed.In addition, we offer guidance on routine maintenance and replacement parts to ensure your safely and efficiently long after the warranty period.

Absolutely! we offer customized screw designs, barrel configurations, feeding systems, and pelletizing systems according to your material and output requirements.

We provide strand pelletizing, water-ring pelletizing, underwater pelletizing, and hot-cut pelletizing systems to match your production needs.

Yes, we provide on-site installation, commissioning, operator training, and after-sales support worldwide.

Type of material to be processed

Target output (kg/h)

Final product form (pellets, sheets, etc.)

Special requirements (e.g. filler loading, color masterbatch, recycling)

Get in Touch with Our Extruder Experts

Looking for a reliable partner for twin screw extruders, masterbatch production, or engineering plastics compounding?

Tell us about your project requirements

We respond to all inquiries within 24 hours. Let’s discuss how we can help you optimize your compounding process and grow your business.

Email: monar330@gmail.com

TEL: +86-13018208126

Don't hesitate, trust us with your project

Trusted by 300+all of world Plastic Manufacturers—Get Your Proposal in 24 Hours!

Submit your requirements today and receive a full quotation, expert guidance, and production priority for your twin screw extruder machine.